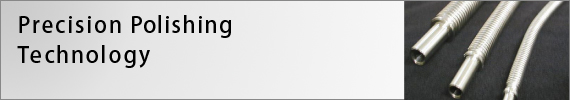

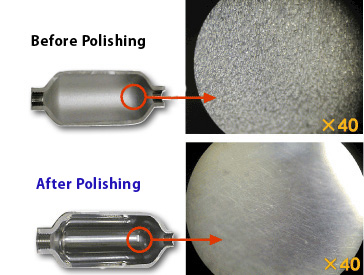

There are various methods for polishing external surface and flat surface.

Our company has been working unflinchingly on the processing methods

and the equipment development for the shapes such as a different diameter pipe,

a deformed tube or a tapered tube and for the materials whose polishing has been

said to be difficult or impossible with conventional methods. If you use our company’s

technologies, we can remove minute burrs without destroying the edges as well as

getting a mirror finish with polishing. We can polish the entire surface of even a

complicated and concavo-convex shape.

Our company has been working unflinchingly on the processing methods

and the equipment development for the shapes such as a different diameter pipe,

a deformed tube or a tapered tube and for the materials whose polishing has been

said to be difficult or impossible with conventional methods. If you use our company’s

technologies, we can remove minute burrs without destroying the edges as well as

getting a mirror finish with polishing. We can polish the entire surface of even a

complicated and concavo-convex shape.

Ultra-Precision Polishing/Mirror Finish

Entire surface polishing of complex configuration

(Material: Cobalt Chrome)

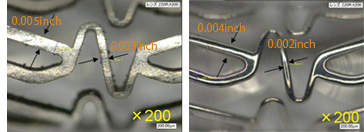

Stent polishing

A stent is a miniature tube that is placed inside a blood vessel or a natural conduit.

The stent acts as a scaffold, pushing against the internal walls of the vessel or

conduit to open a blocked area and thereby enables the natural flow.

Therefore, the smoother surface is required.

Stent polishing

A stent is a miniature tube that is placed inside a blood vessel or a natural conduit.

The stent acts as a scaffold, pushing against the internal walls of the vessel or

conduit to open a blocked area and thereby enables the natural flow.

Therefore, the smoother surface is required.Internal Polishing/Narrow Tube Polishing

Cylinder Interior Polishing (Material:SUS316L)

| By using our special polishing technologies, we can polish the surface of a

part along its original shape. Therefore, we can polish the whole internal surface

of a cylinder which has a discontinuous surface homogeneously.

(See right pictures). |

|

We produce automatic assembly machines and a piece of inspection apparatus with our

original concept that become your advantage to other rival companies that retain

QCD (Quality, Cost, and Delivery) in the field of manufacturing and we deliver them on

a timely basis.

We design and manufacture a wide variety of electronic component assembly equipment that range from vehicle electronic component assembly equipment whose production takt time is about 1 second per piece to carrier machine, work piece supply equipment, pick and place unit, and take-out machine which use cam mechanism.

The number of manufactured products tends to decrease, but products get more varied. We aggressively offer the design and production of semiautomated machines and jigs which keep a high quality and can react promptly to any changes to product specification at quick delivery and a low price.

We have been reliably entrusted with parts processing and production at quick delivery and with a high degree of accuracy by sending or receiving direct data from our clients. We actively process parts at our Chinese factory to meet the needs of our clients at a low cost.

Design and Production of Automated Production Facility

We design and manufacture a wide variety of electronic component assembly equipment that range from vehicle electronic component assembly equipment whose production takt time is about 1 second per piece to carrier machine, work piece supply equipment, pick and place unit, and take-out machine which use cam mechanism.

Production of Semiautomated Device and Jig

The number of manufactured products tends to decrease, but products get more varied. We aggressively offer the design and production of semiautomated machines and jigs which keep a high quality and can react promptly to any changes to product specification at quick delivery and a low price.

Precision Parts Processing

We have been reliably entrusted with parts processing and production at quick delivery and with a high degree of accuracy by sending or receiving direct data from our clients. We actively process parts at our Chinese factory to meet the needs of our clients at a low cost.