We think that the basics of producing automated equipment or laborsaving equipment are

to meet three conditions: space-saving, high functionality, low-cost

The history of the business started when the department of manufacturing contract

(subcontract manufacturing) took the first step into the in-house manufacturing of

production equipment in order to win the competition with our clients (the owner)

or competing rivals in the industry in the field of QCD.

In the initial step of organizing the automation of production process, we start by thoroughly

observing and analyzing the actions of workers (movements of arms, legs, fingers, line of sight)

in the manufacturing floor and the movements of objects (parts and work tools).

As one of the characteristics of development design of our own facilities, there is an idea that

function is nothing special and a compact design to minimize the installation space is necessary.

This is a big challenge to create higher added value through a limited factory space.

We have confidence about the know-how we had accumulated through our great efforts to

meet “space-saving, high functionality, and low cost” at manufacturing premises for

over 30 years.

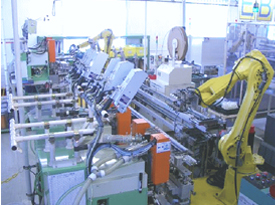

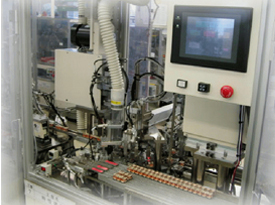

Production Example:1

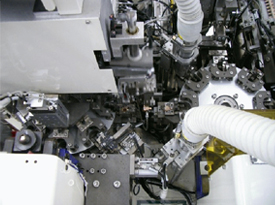

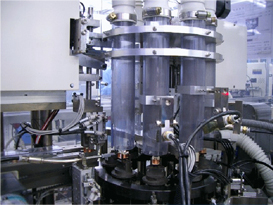

Production Example:2

and demagnetization technology

Production Example:3