Home > Precision Polishing Technology

About Precision Polishing Technology

Our special polishing technique is an original method which was developed by working unflinchingly on the polishing of shapes and materials which many people abandon, saying that the polishing is

difficult or impossible with conventional methods, such as grinding, electrolysis, blast, buff, and barrel.

We can perform mirror finish of a rough surface along the shape. Please see processed examples below.

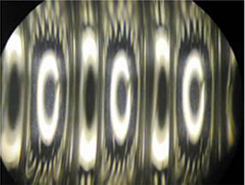

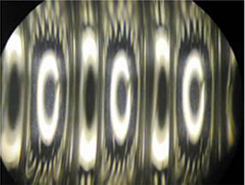

We achieved mirror finish of discontinuous surfaces such as peaks, sides, and valleys of the inner surface of a flexible tube used for semiconductor manufacturing equipment which represent ultra clean technology. As one of the key points of contamination control, there is a surface roughness of the inner surface of a fluid path pipe for pure water, high-purity gas, and chemical. Our special polishing could get the finished surface either equaling or surpassing electrolytic polishing or chemical polishing. Moreover, we can uniformly polish the whole area of the corrugated surface of vaccum seramic pinchuck

In the field of medicine or analytical equipment, the pipes which are narrow and bent, manufactured by spinning or to taper have been increasing, but we can polish them. We can polish pipes, if their inner diameter is 0.003inch and their length is 39.4inch or if their inner diameter is 0.007inch and their length is 78.8inch.

We achieved mirror finish of discontinuous surfaces such as peaks, sides, and valleys of the inner surface of a flexible tube used for semiconductor manufacturing equipment which represent ultra clean technology. As one of the key points of contamination control, there is a surface roughness of the inner surface of a fluid path pipe for pure water, high-purity gas, and chemical. Our special polishing could get the finished surface either equaling or surpassing electrolytic polishing or chemical polishing. Moreover, we can uniformly polish the whole area of the corrugated surface of vaccum seramic pinchuck

In the field of medicine or analytical equipment, the pipes which are narrow and bent, manufactured by spinning or to taper have been increasing, but we can polish them. We can polish pipes, if their inner diameter is 0.003inch and their length is 39.4inch or if their inner diameter is 0.007inch and their length is 78.8inch.

Proven Materials of Precision Polishing Technology

- Stainless Steel SUS303,304,316,316L

- Fine Ceramics Silicon Carbide (SiC), Alumina, Aluminum Nitride

- Titanium

- Nickel Titanium

- Cobalt Chrome

- Inconel

- Hastelloy

- Tantalum

- Aluminum

- Quartz

- Molybdenum

- Zirconia

- Tungsten

Performance and field (Processed Examples)

Semiconductor field

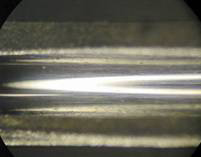

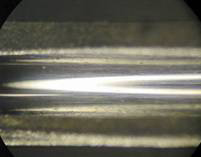

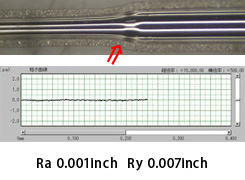

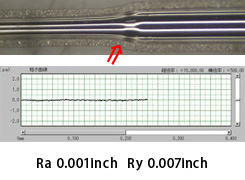

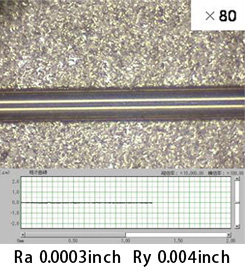

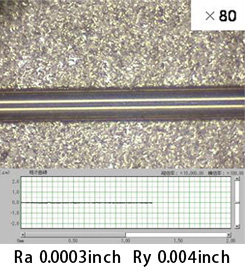

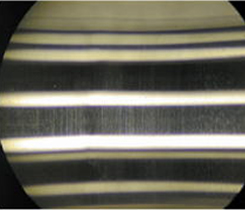

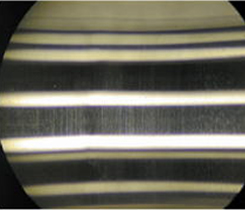

Flexible Tube Interior Polishing(Material:SUS316L)

Before Polishing

After Polishing

Medical and Analysis field

Nozzle Interior Polishing

(Material:SUS304)

This nozzle has been used for the biopsy device.

We can polish from I.D. 0.003inch

Thick tube part O.D. 0.03inch I.D.φ0.7inch

Tubular part O.D. 0.02inch I.D.φ0.4inch

We can polish from I.D. 0.003inch

Thick tube part O.D. 0.03inch I.D.φ0.7inch

Tubular part O.D. 0.02inch I.D.φ0.4inch

Before Polishing

After Polishing

Medical and Analysis field

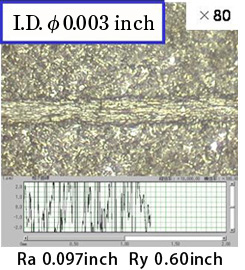

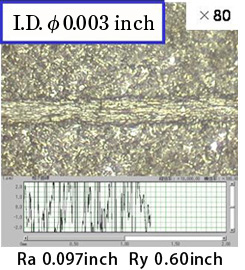

Capillary Tube Interior Polishing(Material

This capillary tube is used for high-performance

Liquid chromatograph column.

I.D.0.003inch~ :Length ~39.4inch

I.D.0.007inch~ :Length ~78.8inch

Liquid chromatograph column.

I.D.0.003inch~ :Length ~39.4inch

I.D.0.007inch~ :Length ~78.8inch

Before Polishing

After Polishing

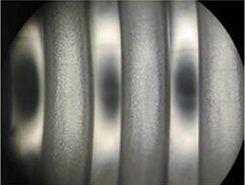

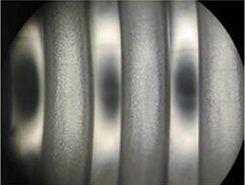

Prefabricated piping

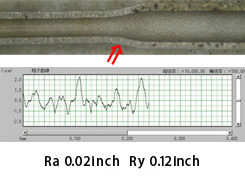

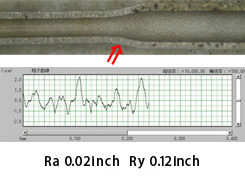

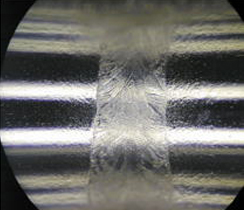

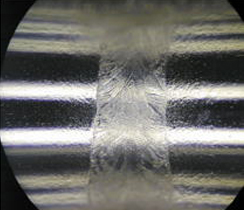

Pipe Welded Part Interior Polishing

(Material:SUS316L)

This pipe is used in gas field. We can polish welded part

and bending part, which is difficult or impossible

with conventional polishing methods.

and bending part, which is difficult or impossible

with conventional polishing methods.

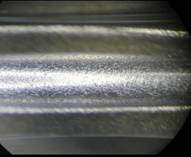

Before Polishing

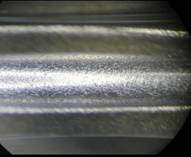

After Polishing

Bending pipe

Material:SUS316L

Before Polishing

After Polishing

Spiral pipe

Material:SUS316L

Before Polishing

After Polishing